HDC prefabricated pits are designed by us as system pits according to the highest quality standards and manufactured within our production facilities. Several production sites and a very high production capacity ensure precise deliveries, even for large projects.

Each prefabricated pit including its equipment is personally inspected by the management of HDC-Fertiggruben GmbH before delivery. A certificate is issued for each acceptance, which is part of the"life cycle file" for the respective pit. Through this measure, the highest quality standard is achieved. Thus we fulfil our own and your promised specifications.

The advantages of HDC prefabricated pits

The different dimensions of our prefabricated pits make them suitable for all types of work under different vehicles, such as under long trucks or buses or even smaller cars. The system pits can be manufactured up to an axle load of 20 t and a surface load of 60 t. This covers the entire range from cars/vans and trucks to the heaviest special vehicles for construction and industry.

The external, approved and liquid-tight special coating ensures optimum protection against corrosion. An additional hard foam insulation serves as temperature compensation and also prevents damage during backfilling in the outdoor area.

Before delivery, the inner pit is sealed with a wax layer against corrosion and contamination during the construction phase. All welded-on steel parts such as brackets, running rails or angle irons are sealed with a creep-resistant, easy-flowing and cavity-filling corrosion agent before painting. This permanently seals all openings. These measures prevent a later "rust flow", which can occur due to capillary penetration of moisture.

Running surface Powerfloor - unique !

Running surface made of "Powerfloor"

Our floors are firmly bonded to the pit bodies and are resistant to water, oil and (to a limited extent) acids.

Properties of the material:

- Fire resistance according to: EN 13501-1

- Slip resistance class: R12

- Hardness grade:A

- Material thickness:5 mm

- Color shade:7016 (dark gray)

Our "PowerFloor" consists of 100% recyclable materials and can be partially replaced and renewed at any time.

Brake tester

Our HDC prefabricated pits are more flexible in the installation of brake testers and articulated playtesters than any other comparable manufacturer. You tell us your desired manufacturer and the corresponding device type and we prepare the respective installation for you. We do not charge extra for the installation of different manufacturers.

You can choose the suitable test stand from different variants. Whether individual test stands or modularly expandable to a complete test lane, there are no limits to your wishes.

Axle play tester

When planning test pits, attention should be paid to the technically correct positioning of the brake tester and the axle play tester. The regulations for "escape routes" must be observed here. With an axle play tester, you can easily detect and localize signs of wear on the wheel and axle suspension. An additional test of the steering and suspension on passenger cars and commercial vehicles can also be carried out.

Pump sump

The drainage is carried out via a pump sump, which in turn can be connected to the oil separator after consultation with the relevant local WHG authority. Alternatively, the pump sump can also be used as a "scoop hole" and thus emptied by manual pumping out. A pump can be installed in the pit at the factory. In this case, appropriate empty pipes are provided from the pump sump to the power supply.

Lamps, compressed air, sockets, control box + maintenance unit

Lamps

The LED lighting consists of polyester damp-proof luminaires and is located in a shock-resistant oval protective tube (IK 07). This is both dust-tight and splash-proof according to IP67.

Compressed air

A compressed air line is already mounted at the factory and includes safety quick couplings with pressure reduction and corrosion protection according to customer requirements. The compressed air line can optionally be replaced with stainless steel piping. An oiler and dehumidifier are provided at the beginning of the regulation. Within the pit, support rails for existing electrical wiring and subsequent installations are also available on request.

ElectricalOutlets

The electrical outlets are already mounted, so you have sufficient power supply for various devices and tools directly on site at any time.

Control box & maintenance unit

The control box as well as the maintenance unit should be freely accessible at all times. This is where you control all units of the prefabricated pit.

Certified prefabricated steel pits from HDC

All HDC pits are

- certified by the DIBt building authorities with the approval no. Z-38.5-300

- manufactured exclusively according to SLW 60

- have a tested statics according to"EUROCODE" standards

- comply with the regulations of AwSV, WHG, TRBS, TRGS

- comply with the accident prevention regulations of the employers' liability insurance association BGR and DGUV

- manufactured on the basis of our quality management according to ISO guidelines

1. demonstration at your place

We come out to you! With our mobile DEMO service, we are happy to visit you at your site and offer you our pit demonstration free of charge and without any obligations. Thus, you will see your future pit live and receive a personal consultation directly at the exhibit.

2. design and production

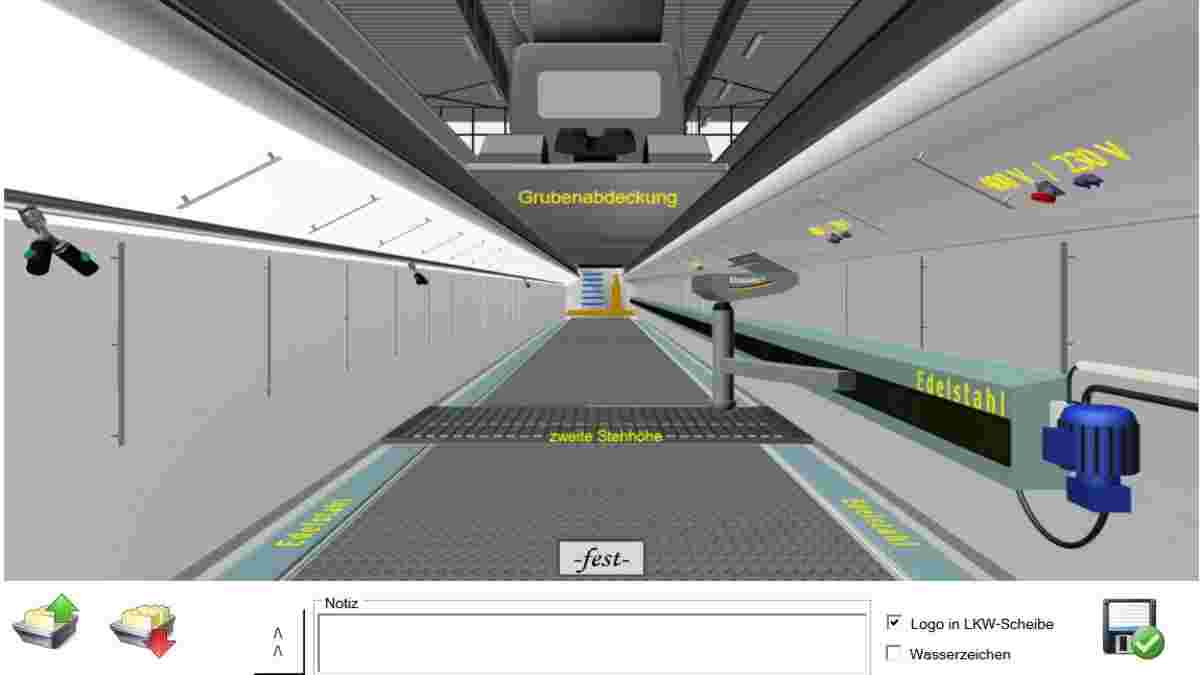

With our 3D pit configurator we realize your wishes immediately and show you your individual desired equipment. After the personal consultation you will receive the configuration of the pit as a file or picture. The configurator allows you an excellent detail representation and thus a high planning reliability.

3. installation and set-up

A part of the preparations is to be taken over by the client. However, we are also happy to offer you the construction services"all from one source": We help you with the selection and correct use of the crane and take over the communication with specialist companies. We are also happy to support you in discussions with authorities and licensing offices.

4. commissioning

After installation, any additional equipment required is installed and tested by the HDC team of experts. Subsequently, a detailed briefing with turnkey handover takes place. A certificate is issued for each acceptance, which, along with important data and execution plans, is part of the life cycle file of your prefabricated pit.

The warranty for HDC prefabricated pits is 24 months. Wear parts or electrical parts, on the other hand, have a warranty of 12 months.

The longevity of our pits is guaranteed by regular cleaning and maintenance. This prevents corrosion caused by external influences. Lack of care will invalidate the warranty. In addition, wear and tear in the course of everyday use is not covered by the warranty.

In general, measures for fire, UVV and waste water regulations are to be taken over by the client.

In preparation for the pit installation, an appropriately calculated and tested base plate is to be created. We are happy to offer you the construction services from a single source.

In addition, a crane is required for the assembly of the prefabricated pit. For the correct selection and use of this construction machine we gladly take over the communication with the specialized enterprise assigned by you. The load to be carried by the crane results from the design and the length of the pit and will be communicated to you before delivery.

Permits and acceptance of the building object are not part of our services. The site plan is to be provided by you as the client on your own initiative. Here, too, we will be happy to support you in discussions with the licensing authorities and government agencies.

On the day of pit installation, access to the construction site and an appropriate parking space for the mobile crane must be organised. The crane must be provided by the customer and must be set up and ready to move in good time on the day of installation. Date and time are to be coordinated exactly in advance.

Furthermore, a paved, level open area of at least 3 m should be available around the foundation.

The HDC prefabricated pits have the following basic or standard equipment:

- Standard stairs

- Pump sump

- Stairs for parking position Floor running pit lift

- choice of working width and standing height up to 1.60 m

- pits are supplied in SLW 60 (no extra charge)

- upper pit frame equipped with running rail profile

- Fixing bolts for subsequent attachments

- DiBT approval for authorities and approval bodies

- Non-slip and easy to maintain checker plate floor, grating or a combination of both

- LED lighting

- Compressed air cleaning

- Stainless steel rails for the floor-running pit lift

- Second standing height

- Walk-on wooden construction cover and weatherproof plastic tarpaulin in the upper pit frame

The following equipment elements can be added individually and, if required, can already be fitted at the factory:

- Wheel deflector

- Installation frame for brake tester and joint play tester

- Eagle's nest/niche

- Roller cover

- HDC-Snake

- Undersnake" roller cover

- Side access

- Pit heating

- Oil supply systems and data management

The standard measurement for the width is approx. 0.9 - 1.05 m. For vehicles with a lot of ground clearance (trucks), a depth standard value of 1.39 m applies. For vehicles with little ground clearance (buses) approx. 1.49 m.

From a depth of 1.60 m, however, the regulations for a necessary forced ventilation must also be observed.

What the media say about our prefabricated steel pits

Your prefabricated pits A-Team: Get to know us personally

Expert advice

South

Michael Krönig

+49 (0) 7121 26726 40

+49 (0) 1738077596

m.kroenig@kroenig.org

Zum Wäldle 11

D 72768 Reutlingen